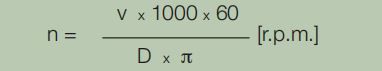

One of the important factors in the design of a conveyor is the speed of the belt movement in relation to the load conditions required. From the belt speed and roller diameter we can determine the revolutions per minute of the roller using the formula:

Where:D = roller diameter [mm] v = belt speed [m/s]

The following table gives the existing relationship between maximum belt speed, roller diameter and the relative r.p.m.In choosing the roller it is interesting to note that even if a roller of larger diameter exhibits a higher inertia on start up,it actually yields, other conditions being equal, many advantages such as: less revolutions per minute, less wear of bearings and housing, less rolling friction and reduced wear between the roller and the belt.

Maximum speed and numbers of roller revolutions

|

Roller Diameter mm |

Belt speed m/s |

R.p.m.n |

|

50 |

1.5 |

573 |

|

63 |

2.0 |

606 |

|

76 |

2.5 |

628 |

|

89 |

3.0 |

644 |

|

102 |

3.5 |

655 |

|

108 |

4.0 |

707 |

|

133 |

5.0 |

718 |

|

159 |

6.0 |

720 |

|

194 |

7.0 |

689 |

The correct choice of diameter must take into consideration the belt width.

The following table shows the diameter of rollers in relation to belt width.

|

For speed≤2m/s φroller mm |

2-4m/s φroller mm |

≥4m/s φroller mm |

|||||||

|

500 |

89 |

89 |

|||||||

|

650 |

89 |

89 |

108 |

||||||

|

800 |

89 |

108 |

89 |

108 |

133 |

133 |

|||

|

1000 |

108 |

133 |

108 |

133 |

133 |

159 |

|||

|

1200 |

108 |

133 |

108 |

133 |

159 |

133 |

159 |

||

|

1400 |

133 |

159 |

133 |

159 |

133 |

159 |

|||

|

1600 |

133 |

159 |

133 |

159 |

194 |

133 |

159 |

194 |

|

|

1800 |

159 |

159 |

194 |

159 |

194 |

||||

|

2000 |

159 |

194 |

159 |

194 |

159 |

194 |

|||

|

2200 and more |

194 |

194 |

194 |

||||||