- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Carbon Steel Troughing Roller

Carbon Steel Troughing Roller

Carrying roller,troughing roller,impact roller,return spiral roller,return sleeve roller

Introduction to Carbon Steel Troughing Roller

Structure:

The Carbon Steel Troughing Roller is an essential component in conveyor systems, facilitating the smooth movement of materials. Manufactured with precision and quality, these rollers play a crucial role in various industries. Composed of durable carbon steel, they offer robust support for heavy loads and harsh environments.

Product Standards:

Our Carbon Steel Troughing Roller adheres to stringent industry standards, ensuring reliability and performance. They comply with international quality certifications, including ISO 9001:2015, guaranteeing consistency in manufacturing and product excellence.

Product Attributes:

Robust Construction: Crafted from high-grade carbon steel, ensuring durability and longevity.

Precision Bearings: Equipped with precision sealed bearings for smooth operation and reduced maintenance.

Customizable: Available in various sizes and configurations to suit specific conveyor requirements.

Product Functions:

The carbon Steel Troughing Roller supports conveyor belts, guiding them and facilitating the efficient movement of materials. They minimize friction, preventing belt damage and enhancing overall conveyor performance.

Features:

Corrosion Resistance: Coated with powder or galvanized for protection against corrosion and environmental elements.

High Load Capacity: Capable of handling heavy loads, ideal for industries requiring bulk material handling.

Low Maintenance: Designed for minimal upkeep, reducing downtime and operational costs.

Advantages and Highlights:

Exceptional Durability: Manufactured with premium materials, ensuring long-lasting performance even in demanding applications.

Versatility: Suitable for various industries such as mining, construction, agriculture and logistics.

Enhanced Efficiency: Promotes smooth material flow, optimizing production processes and increasing throughput.

Application Areas:

The carbon Steel Troughing Roller finds extensive use in industries requiring conveyor systems, including:

Mining and Quarrying

Manufacturing

Agriculture and Aggregates

Warehousing and Distribution

OEM Service:

We offer OEM services, catering to specific requirements and customization needs. Our experienced team ensures seamless integration with existing systems, providing tailored solutions for diverse applications.

FAQ:

Q: Can you customize roller dimensions?

A: Yes, we offer customization services to meet specific roller diameter and shaft diameter requirements.

Q: What surface treatments do you provide? A: We provide options for powder coating or galvanization to enhance corrosion resistance and prolong roller lifespan.

Contact Information:

For inquiries or to place an order, please get in touch with us at angie@idlerchina.com. We are an integrated enterprise specializing in scientific research, production, processing and sales of conveyor components.

Conclusion:

The carbon Steel Troughing Roller are indispensable component in conveyor systems, offering durability, reliability and efficiency. With customizable options and superior performance, they are the preferred choice for professional buyers and global dealers across various industries.

CARBON STEEL TROUGHING ROLLER INTRODUCTION

We Cangzhou Idler Conveyor Machinery Co., Ltd can produce a complete range of conveyor rollers for bulk materials handling applications in mining, quarrying, recycling, cement, brick, power, grain and other conveyor type handling systems. Our conveyor roller range includes carrier roller, trough roller, return roller, rubber disc impact roller and sleeve roller, friction roller, guide roller and designs with idler roller diameters from 50 mm to 219mm in both carbon steel, stainless steel, PVC, Nylon and UHMWPE (polymer) across conveyor belt width up to 3500mm.

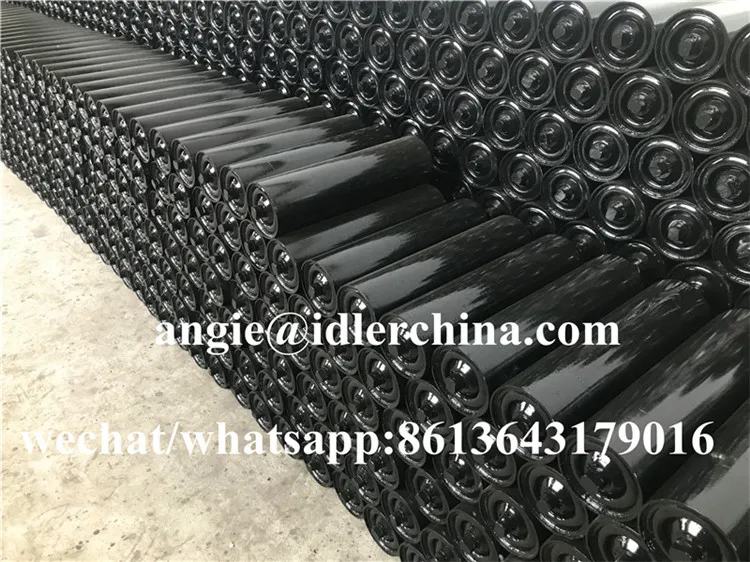

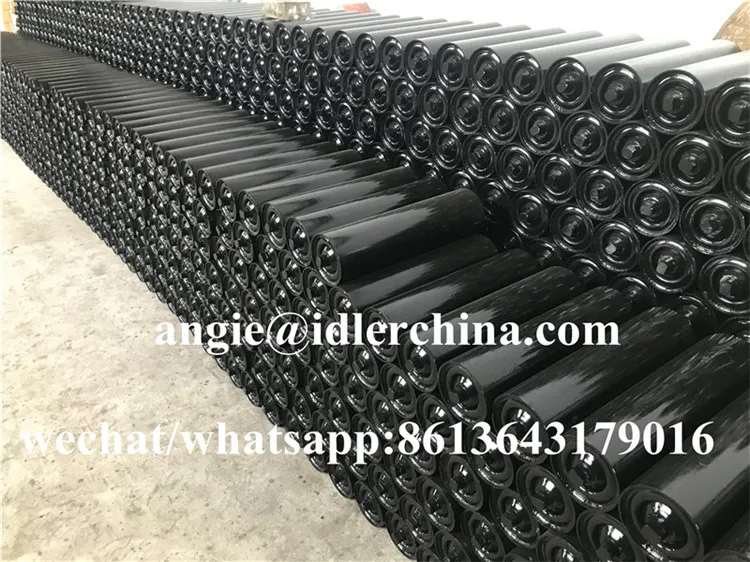

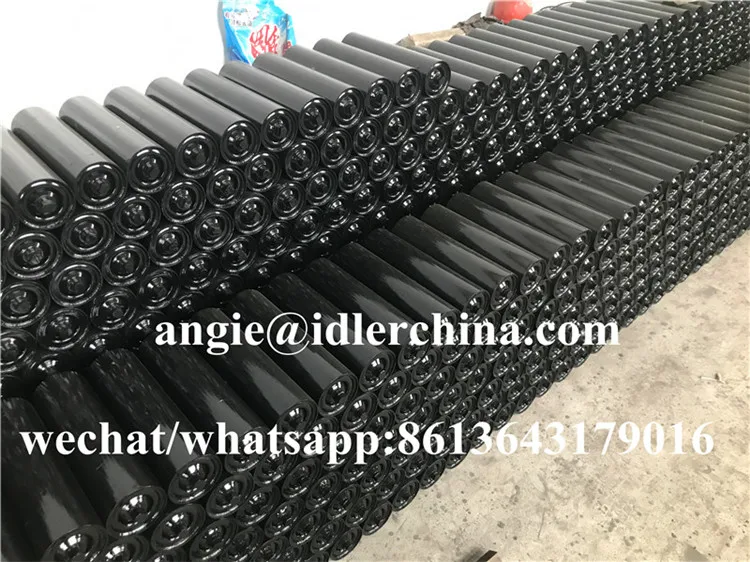

CARBON STEEL TROUGHING ROLLER PRODUCT SHOW

CARBON STEEL TROUGHING ROLLER EACH PART INTRODUCTION

1. Manufactured with steel pipe especially for high precision roller, compared with ordinary steel pipe, the diameter and wall thickness tolerance, bending degree and ovality are very little which can make the roller have minimum radial play eccentricity, strong load, low shaking and less noise

2. High precision and brightness cold drawn shaft with 1045 material

3. Rollers are fitted with deep groove 2RS and 2Z bearings with C3 and C4 internal clearance with HRB, SKF, NSK, TNT, FAG brands.

4. Bearing Housing formed by punching many times which can assure high precision. The wall thickness is 1-2mm thicker than the DIN standard which can increase 40% stability and roller's carrying capacity. It can make the roller not deformed even when working under an overloaded environment and increase the roller’s lifetime.

5. TK contact multiple labyrinth seals made of nylon, ABS have great advantage in water and dust resistance

CARBON STEEL TROUGHING ROLLER PACKAGE AND DELIVERY

OTHER RELATED PRODUCTS

CUSTOMERS VISIT, SINCERELY WELCOME YOU TO COME TO OUR FACTORY

Hot Tags: carbon steel troughing roller, China, suppliers, manufacturers, factory, customized, wholesale, cheap, pricelist, buy discount, low price, in stock, for sale, free sample, made in China, HDPE Conveyor Roller, Plastic Conveyor Rollers, Steel Conveyor Roller, Conveyor Roller, Metal Conveyor Rollers, Conveyor Roller Sets

YOU MAY LIKE