- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

How to determine the shaft diameter of conveyor drum pulley

2024-02-21 17:14:36

Bearing Centers & Hub Centers

The distance between the center of each bearing support and the center of each hub connection will impact the degree to which the shaft deflects and should be accounted for when selecting a shaft diameter. Having a greater distance between the hub centers and the bearing centers will require a larger diameter shaft to accommodate the same load.

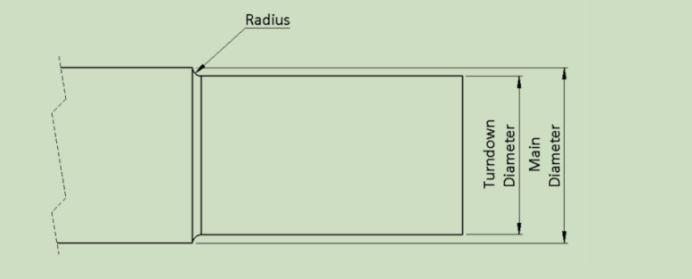

Turndowns

When the physical constraints of a conveyor system will not allow you to properly size your shaft diameter, shaft turndowns may be utilized to increase the load capacity of a pulley. A turndown is where a larger shaft is turned down to a smaller diameter at the ends, while retaining the larger diameter through the pulley.

The sudden change in geometry between a shaft major diameter and a turndown is an area of stress concentration. A radius should be incorporated to reduce the stress concentration at this point.

Product Load and Loading Method

In addition to providing some degree of belt tension to the conveyor system, the load of the conveyed product can also contribute to the load being directly applied to the conveyor pulley. This becomes a more significant factor when the product is being loaded on the conveyor in an area near the pulleys. The greater the amount of load applied to the pulley, the greater the shaft diameter required to properly support the load.