- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Heavy Duty Conveyor Rollers

Heavy Duty Conveyor Rollers

Introduction to Heavy Duty Conveyor Rollers

Structure:

Heavy Duty Conveyor Rollers are fundamental parts in different businesses for productive material dealing with and transportation. Intended to endure high loads and cruel working circumstances, these rollers assume a basic part in guaranteeing smooth and solid development of products along transport frameworks. In this exhaustive presentation, we'll dig into the vital parts of substantial transport rollers, including item subtleties, principles, ascribes, capabilities, highlights, benefits, application regions, OEM administrations, and regularly got clarification on some pressing issues (FAQs).

Basic Product Details:

They are commonly produced using hearty materials like steel or treated steel, guaranteeing strength and life span in requesting conditions. They come in different measurements, lengths, and burden abilities to oblige different transport framework prerequisites.

Product Standards:

Heavy duty conveyor rollers adhere to industry standards and specifications to ensure compatibility and safety in diverse applications. These standards may include dimensional tolerances, material composition, load-bearing capacities, and performance criteria set forth by regulatory bodies and industry organizations.

Basic Parameters:

Below are some basic parameters commonly associated with heavy duty conveyor rollers, presented in table form:

| Parameter | Description |

|---|---|

| Diameter | Various sizes available, typically ranging from X to Y |

| Length | Customizable to suit specific conveyor dimensions |

| Load Capacity | High load-bearing capacity to support heavy loads |

| Material | Steel, stainless steel, or other durable materials |

| Surface Treatment | Options include galvanization, powder coating, etc. |

Product Attributes:

They exhibit several key attributes, including robust construction, precision engineering, corrosion resistance, and low maintenance requirements. These attributes contribute to their reliability and performance in challenging industrial environments.

Product Functions:

They serve the primary function of facilitating the smooth and efficient movement of goods along conveyor systems. They provide support, traction, and guidance to conveyor belts, ensuring optimal material handling operations.

Features, Advantages, and Highlights:

High Load Capacity: Engineered to withstand heavy loads, ensuring reliable performance in industrial applications.

Durable Construction: Made from quality materials, offering long-term durability and resistance to wear and tear.

Versatile Design: Available in various configurations to accommodate different conveyor system layouts and requirements.

Low Friction: Precision bearings and smooth surfaces minimize friction, reducing energy consumption and maintenance needs.

Easy Installation: Designed for quick and hassle-free installation, minimizing downtime during system setup or maintenance.

Application Areas:

Substantial transport rollers track down broad utilization across assorted ventures, including:

Mining and quarrying

Producing

Coordinated operations and conveyance

Development

Horticulture

Warehousing

OEM Service:

As an enterprise integrating scientific research, production, processing, and sales, we offer OEM services to meet custom requirements and specifications. Whether you need tailored solutions or private labeling, our team is committed to delivering high-quality heavy duty conveyor rollers to suit your unique needs.

FAQ:

Q: Can you provide customized solutions for unique conveyor system layouts? A: Yes, we offer customization services to tailor it to suit your unique layout and operational requirements. Just give us your details, and our designing group will work intimately with you to foster the best arrangement.

For inquiries or orders, please contact us at angie@idlerchina.com.

Conclusion:

In conclusion, they are indispensable components in modern material handling systems, offering durability, reliability, and performance in demanding industrial environments. With a focus on quality, versatility, and customer satisfaction, our enterprise is committed to delivering premium it tailored to meet the diverse needs of professional buyers and global dealers.

Heavy Duty Conveyor Rollers:

We make customized heavy duty conveyor rollers which meet CEMA E standard for clients from Chile. The roller diameter is 159mm and 178mm with 6307 and 6308 bearing.

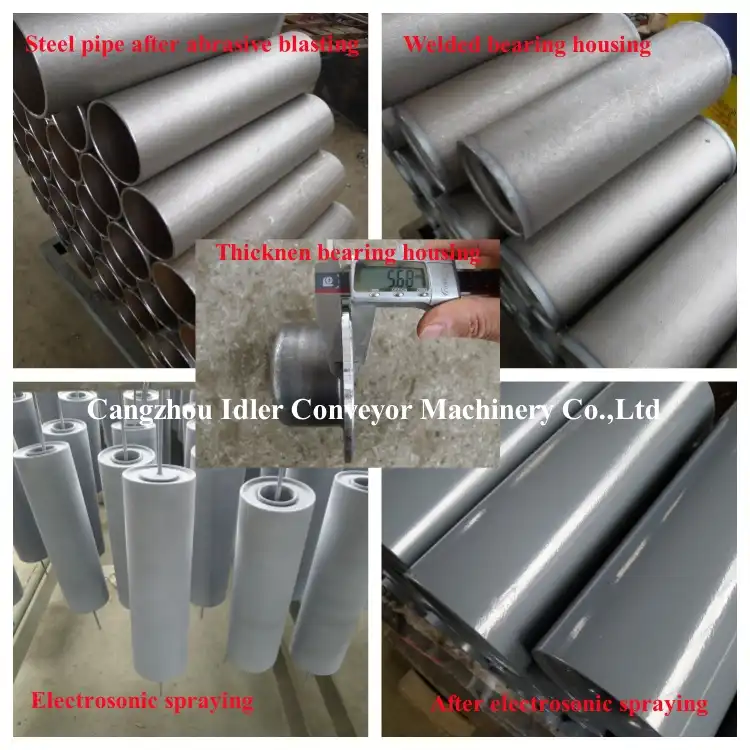

Heavy Duty Conveyor Roller Advantage:

1.Use steel pipe specially for making conveyor roller which can reduce conveyor roller's radial runout

2.Use thicken bearing housing,more than 5mm thick

3.Dust and water proof labyrinth seals which can used under severe working condition

Hot Tags: heavy duty conveyor rollers, China, suppliers, manufacturers, factory, customized, wholesale, cheap, pricelist, buy discount, low price, in stock, for sale, free sample, made in China, Plastic Conveyor Rollers, Conveyor Return Roller, Conveyor Impact Roller, Conveyor Roller Sales, Conveyor Roller, PU Coat Roller

YOU MAY LIKE