- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

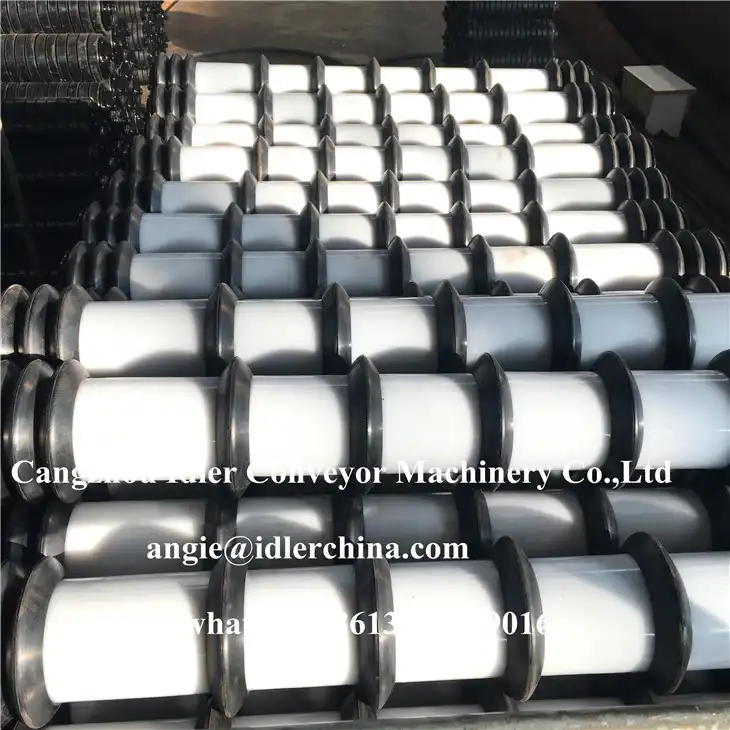

conveyor impact idler

Conveyor Impact Idler

Product Introduction

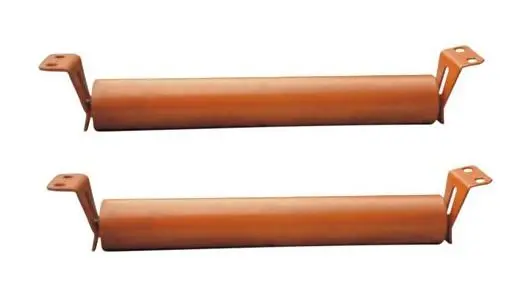

The Conveyor Impact Idler is an essential component in conveyor systems, specifically designed to absorb and distribute the impact forces that occur when bulk materials are loaded onto the conveyor belt. This product ensures the longevity and efficiency of conveyor systems by minimizing damage to the belt and idlers, thus reducing maintenance costs and extending equipment life.

At Cangzhou Idler Conveyor Machinery Co., Ltd, we leverage decades of expertise to produce high-quality conveyor impact idlers that meet the rigorous demands of global industries. With a commitment to excellence, we incorporate advanced technology and precise engineering into every product we manufacture.

Founded in 1980, Cangzhou Idler Conveyor Machinery Co., Ltd has evolved from a small-scale manufacturer into a leading producer in the conveyor machinery sector. Our state-of-the-art production facilities in Yanshan County, Hebei Province, are equipped with sophisticated equipment and staffed by experienced professionals dedicated to producing superior conveyor components.

Product Specifications

| Specification | Value |

|---|---|

| Diameter | 89 mm, 108 mm, 114 mm |

| Length | 600 mm, 800 mm, 1000 mm |

| Roller Material | Steel, Rubber |

| Bearing Type | Sealed Ball Bearing |

| Maximum Load Capacity | 500 kg, 1000 kg |

| Temperature Range | -20°C to 60°C |

| Surface Treatment | Galvanized, Powder Coated |

Physical and Chemical Properties

- Material Composition: High-strength steel and impact-resistant rubber.

- Corrosion Resistance: Galvanized coating ensures excellent resistance to environmental factors and corrosion.

- Impact Resistance: Engineered to withstand high-impact forces, protecting the conveyor belt and extending its operational life.

Mechanical Performance

- Durability: Designed to endure severe impact forces, reducing wear and tear on both the idler and the conveyor belt.

- Load Distribution: Effectively distributes the load across the idler, minimizing localized stress and preventing damage.

- Reduced Vibration: The impact idler’s design minimizes vibration, which helps in maintaining smooth conveyor operations.

- Low Maintenance: With high-quality bearings and robust construction, our impact idlers require minimal maintenance, resulting in lower operational costs.

Product Applications

- Mining: Protects conveyor systems from the heavy and abrasive materials transported in mining operations.

- Steel Production: Ideal for handling bulk steel products, reducing impact on the conveyor system.

- Cement Manufacturing: Ensures the smooth transport of cement and other bulk materials, minimizing downtime.

- Power Plants: Enhances the reliability of conveyor systems used for coal and other fuel materials.

- Ports and Harbors: Essential for bulk material handling in shipping and receiving operations.

The trend towards increased automation and higher throughput in industrial operations continues to drive demand for advanced conveyor components. Our impact idlers are designed to meet these evolving needs, ensuring reliability and performance in modern conveyor systems.

Manufacturing Process and Production Flow

- Design and Engineering: Advanced CAD software is used for precise design and engineering of impact idlers.

- Material Selection: High-quality materials are chosen to ensure durability and performance.

- Fabrication: State-of-the-art machinery is used to fabricate components with high precision.

- Assembly: Components are carefully assembled and tested to ensure they meet quality standards.

- Quality Control: Each product undergoes rigorous testing and inspection to guarantee reliability and performance.

- Packaging: Finished products are packaged to prevent damage during transit.

Our Factory

Cangzhou Idler Conveyor Machinery Co., Ltd operates a 25,000 square meter facility located in Yanshan County, Hebei Province. Our factory is equipped with advanced production and testing equipment, enabling us to deliver high-quality products. Our team of 186 skilled professionals, including 20 senior engineers and 40 technicians, ensures that every product meets our stringent quality standards.

We are committed to continuous improvement and innovation, leveraging our extensive experience and technological advancements to produce industry-leading conveyor components.

Packaging

- Wooden Crates: Provides robust protection for impact idlers during long-distance transport.

- Carton Boxes: Suitable for smaller quantities and offers cost-effective protection.

- Foam Padding: Ensures cushioning and prevents damage to sensitive parts.

- Waterproof and Moisture-Proof Packaging: Protects products from environmental factors.

- Custom Packaging: Tailored solutions to meet specific customer requirements and international standards.

Logistics

- Sea Freight: Cost-effective for large shipments and global distribution.

- Air Freight: Fast delivery for urgent orders.

- Land Transport: Efficient for regional deliveries within China.

- Multimodal Transport: Combines different transportation modes for optimal efficiency.

- Courier Services: Ideal for small, time-sensitive shipments.

Why Choose Us

- Established Expertise: Over 40 years of experience in conveyor machinery production.

- Advanced Facilities: Equipped with modern technology and quality control systems.

- Comprehensive Product Range: Offering a wide variety of conveyor components and parts.

- Global Reach: Products exported to numerous countries, ensuring international standards.

- Customer-Centric Approach: Focused on providing high-quality products and exceptional after-sales service.

OEM Services

Cangzhou Idler Conveyor Machinery Co., Ltd offers customized OEM/ODM services to meet specific client requirements. We work closely with customers to develop tailored solutions that align with their unique needs and specifications.

FAQ

-

What is the primary function of a conveyor impact idler?

- Conveyor impact idlers absorb the impact forces from bulk materials being loaded onto the conveyor belt, reducing damage and extending the life of the conveyor system.

-

What materials are used in the construction of impact idlers?

- Our impact idlers are made from high-strength steel and impact-resistant rubber, ensuring durability and performance.

-

What is the maximum load capacity of your impact idlers?

- Our impact idlers can handle loads up to 1000 kg, depending on the size and specifications.

-

Can impact idlers be customized for specific applications?

- Yes, we offer OEM/ODM services to customize impact idlers according to your specific needs.

-

What is the typical lead time for an order?

- The lead time varies based on order size and customization requirements. Generally, it ranges from 4 to 6 weeks.

Contact Us

We invite you to explore the benefits of partnering with Cangzhou Idler Conveyor Machinery Co., Ltd. For inquiries, custom orders, or further information, please reach out to us at angie@idlerchina.com. Our team is ready to assist you and ensure your conveyor systems operate at peak efficiency.

YOU MAY LIKE