- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

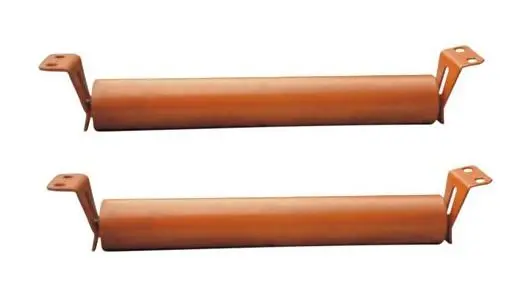

idler rolls belt conveyor

Product Introduction

Cangzhou Idler Conveyor Machinery Co., Ltd. proudly presents our state-of-the-art idler roller belt conveyors, engineered to meet the highest industry standards. Established in 1980, our company has consistently delivered exceptional conveyor solutions that cater to a diverse range of industries, including mining, steel, cement, power, and chemical sectors. Our idler rollers are crucial components in ensuring efficient and reliable material handling systems.

Idler roller belt conveyors are vital in the bulk material handling process. They support and guide the conveyor belt, enabling smooth transportation of materials across various distances. Our idler rollers are designed to withstand harsh operating conditions, reduce friction, and enhance the overall efficiency of conveyor systems.

At Cangzhou Idler Conveyor Machinery Co., Ltd., we are committed to delivering products that excel in performance and durability. Our idler rollers are manufactured with precision and undergo rigorous quality control to ensure they meet the highest standards. With over four decades of expertise, we offer products that not only meet but exceed industry expectations.

Product Parameters

Below are the detailed specifications for our idler roller belt conveyors:

| Parameter | Specification |

|---|---|

| Roller Diameter | 50mm, 76mm, 89mm, 108mm |

| Roller Length | 500mm, 1000mm, 1500mm, 2000mm |

| Material | Steel, Stainless Steel, PVC |

| Bearing Type | Deep Groove Ball Bearing, Spherical Roller Bearing |

| Load Capacity | Up to 2000 kg |

| Temperature Range | -20°C to +80°C |

| Surface Finish | Powder Coated, Galvanized, Painted |

Physical and Mechanical Properties

Physical Properties:

- Material Strength: Our rollers are manufactured from high-strength steel and stainless steel, offering superior resistance to wear and tear.

- Corrosion Resistance: With options for galvanizing and powder coating, our rollers are protected against rust and corrosion.

- Durability: Designed for long-term use, our idler rollers maintain their integrity under continuous operation.

Mechanical Properties:

- Load Bearing Capacity: Each roller is engineered to support heavy loads while maintaining smooth operation.

- Friction Reduction: Precision bearings and high-quality materials ensure minimal friction and reduced energy consumption.

- Noise Reduction: Designed to operate quietly, reducing noise pollution in industrial environments.

Product Applications

Our idler roller belt conveyors are versatile and suitable for various applications:

- Mining: Efficiently transport ore, coal, and other materials from extraction points to processing facilities.

- Steel Industry: Handle heavy steel products and scrap materials with ease.

- Cement Production: Support the transportation of raw materials and finished products in cement plants.

- Power Plants: Facilitate the movement of coal, ash, and other materials essential to power generation.

- Chemical Industry: Ensure safe and efficient transport of chemicals and powders.

- Agriculture: Convey grains, fertilizers, and other agricultural products.

Trends in Application:

- Automation: Increasing integration with automated systems for enhanced efficiency.

- Environmental Considerations: Development of eco-friendly materials and designs to reduce environmental impact.

- Customization: Growing demand for tailored solutions to meet specific industry needs.

Production Processes

1.Use automatic pipe cutting machine to cut steel pipe which for making conveyor roller specially into fixed length. This type of steel pipe is more precise than seamless steel pipe and ordinary straight seam steel pipe and can reduce conveyor roller’s run out.

2.Turning steel pipe inside diameter to install bearing housing

3.Welding bearing housing

4.Mill conveyor roller shaft with flat or groove end

5.Mill circlip groove on conveyor roller shaft

6.Press assemble conveyor roller labyrinth seals and bearing.We will choose TK labyrinth seals which have great advantage in dust proof and water proof and high quality raw material of ABS,Nylon,Hdpe,Polyurethane and so on.

7.Surface Treatment: Anti-corrosion treatments are applied to enhance durability.

8.Quality Control: Rigorous testing is conducted to ensure each product meets our high standards.

9.Packaging: Products are carefully packaged to prevent damage during transportation.

Company Introduction

Founded in 1980, Cangzhou Idler Conveyor Machinery Co., Ltd. is a leading manufacturer specializing in conveyor components. Our facilities cover 25,000 square meters and are equipped with advanced production and testing equipment. We pride ourselves on our comprehensive quality control system, ensuring that every product meets international standards.

Our team comprises 186 dedicated professionals, including 20 senior engineers and 40 technicians. We serve various industries worldwide, with a commitment to delivering high-quality products and exceptional service. Our products are exported to countries including Japan, Saudi Arabia, the United States, and Brazil.

Logistics and Packaging

Packaging Options:

- Wooden Crates: For secure and safe transport, especially for bulk orders.

- Cartons: Standard packaging for smaller quantities, ensuring product protection.

- Foam Filling: Additional cushioning to prevent damage during transit.

- Waterproof Packaging: To safeguard against moisture and environmental conditions.

- Custom Packaging: Tailored solutions to meet specific client requirements.

- International Standards: Compliance with global packaging standards for secure delivery.

Logistics Options:

- Sea Freight: Cost-effective for large orders, with reliable international shipping.

- Air Freight: Fast delivery for urgent orders, with global reach.

- Land Transport: Efficient for regional deliveries and domestic shipping.

- Multimodal Transport: Combining different transport methods for optimal efficiency.

- Courier Services: Expedited shipping for smaller orders and urgent requirements.

Why Choose Us

- Established Expertise: Over four decades of experience in conveyor solutions.

- Advanced Facilities: State-of-the-art production and testing equipment.

- Comprehensive Quality Control: Rigorous testing and quality assurance processes.

- Global Reach: Exporting to numerous countries with a strong international presence.

- Customer-Centric Approach: Focused on providing high-quality products and exceptional service.

- Custom Solutions: Tailored products and services to meet specific industry needs.

OEM Services

At Cangzhou Idler Conveyor Machinery Co., Ltd., we offer customized solutions to meet your unique requirements. Our OEM services include:

- Custom Design: Tailored roller designs to fit specific applications.

- Material Options: Choice of materials and finishes to suit different environments.

- Private Labeling: Branding options to align with your company’s identity.

- Flexible Production: Adaptable manufacturing processes to accommodate various order sizes.

FAQs

-

What materials are used in your idler rollers?

- Our idler rollers are made from high-strength steel, stainless steel, and PVC.

-

What is the maximum load capacity of your idler rollers?

- Our rollers can support loads up to 2000 kg.

-

Do you offer customized solutions?

- Yes, we provide OEM services for custom designs and specifications.

-

What is the standard lead time for an order?

- The standard lead time is typically 4-6 weeks, depending on the order size and customization.

-

How do you ensure the quality of your products?

- We employ a comprehensive quality control system, including rigorous testing and inspection.

Contact Us

We invite global buyers to partner with Cangzhou Idler Conveyor Machinery Co., Ltd. for high-quality idler roller belt conveyors. For inquiries and quotations, please contact us at:

Email: angie@idlerchina.com

Phone: 13643179016

Address: Industrial Zone, Yanshan County, Hebei Province, China

We look forward to establishing a long-term and mutually beneficial relationship with you. Let us help you enhance your material handling systems with our reliable and efficient products.

YOU MAY LIKE