- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

idlers for belt conveyor systems

Idlers for Belt Conveyor Systems

Product Introduction

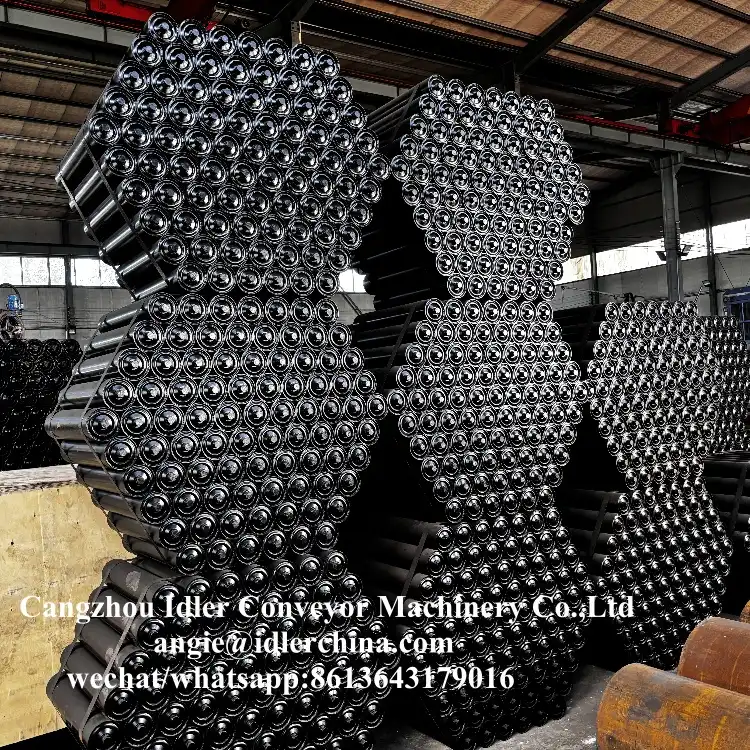

Welcome to Cangzhou Idler Conveyor Machinery Co., Ltd., your premier source for high-quality idlers for belt conveyor systems. Established in 1980, we are a leading manufacturer specializing in the design and production of conveyor components, including idlers, rollers, and pulleys. Our idlers are essential components in various industries, including mining, steel, cement, power, and more.

Idlers are critical for maintaining the efficiency and longevity of conveyor systems. They support the conveyor belt and ensure smooth operation by reducing friction and wear. Our idlers are engineered to meet the highest standards of durability and performance, making them a reliable choice for demanding applications.

At Cangzhou Idler Conveyor Machinery Co., Ltd., we pride ourselves on our commitment to quality and innovation. Our idlers are manufactured using advanced technology and materials, ensuring that they meet international standards and provide exceptional performance in a wide range of environments.

Product Parameters

| Parameter | Specification |

|---|---|

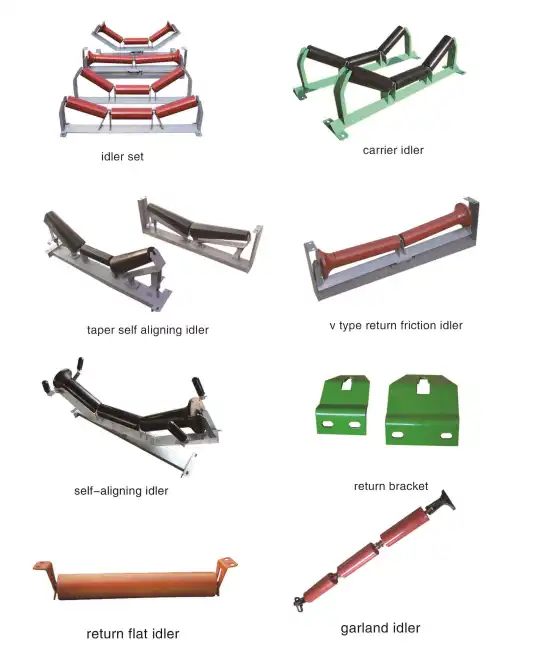

| Idler Type | Trough, Impact, Return, Training |

| Roller Diameter | 89mm, 108mm, 114mm, 133mm |

| Roller Length | 400mm to 3000mm |

| Tube Material | Steel, Stainless Steel, Aluminum |

| Bearing Type | Sealed, Open, Self-lubricating |

| Load Capacity | Up to 50 tons |

| Working Temperature | -20°C to +60°C |

| Corrosion Resistance | High |

| Certification | ISO 9001, CE, SGS |

Physical and Mechanical Properties

Physical Properties

- Material Composition: Our idlers are made from high-quality steel, stainless steel, and aluminum, ensuring robustness and durability.

- Surface Finish: The rollers are treated with anti-corrosive coatings and finishes, including powder coating and galvanization, to enhance longevity and resistance to harsh environments.

Mechanical Properties

- Load Bearing Capacity: Designed to withstand heavy loads, our idlers offer superior strength and stability.

- Bearing Performance: Equipped with high-performance bearings that provide smooth rotation and minimize friction.

- Impact Resistance: Our impact idlers feature reinforced construction to absorb shocks and reduce conveyor belt wear.

Product Applications

Our idlers are versatile and can be used in a variety of applications, including:

- Mining: Ideal for heavy-duty mining operations, handling large volumes of material with high efficiency.

- Steel Industry: Used in steel plants to transport raw materials and finished products.

- Cement Industry: Suitable for conveying cement and other bulk materials, ensuring reliable performance in challenging conditions.

- Power Plants: Essential for transporting coal, ash, and other materials in power generation facilities.

- Ports and Harbors: Designed for use in port facilities, handling various bulk materials and cargo.

Trends and Developments:

- Increasing Automation: The trend towards automated conveyor systems is driving demand for more advanced idlers with integrated sensors and monitoring capabilities.

- Enhanced Durability: Advances in materials and coatings are improving the lifespan and performance of idlers in extreme environments.

- Energy Efficiency: Innovations aimed at reducing energy consumption and enhancing the efficiency of conveyor systems are becoming more prevalent.

Product Process and Production Flow

- Design and Prototyping: Our team of engineers and designers create detailed specifications and prototypes for new idler models.

- Material Selection: High-quality materials are sourced and tested to meet stringent standards.

- Manufacturing: Advanced machinery and techniques are used to manufacture idlers with precision.

- Quality Control: Each idler undergoes rigorous testing and quality checks to ensure it meets our high standards.

- Assembly: Components are assembled and integrated into the final product.

- Packaging and Shipping: Idlers are carefully packaged and shipped to customers around the world.

Company Introduction

Cangzhou Idler Conveyor Machinery Co., Ltd. was founded in 1980, integrating scientific research, production, processing, and sales. Located in the Industrial Zone of Yanshan County, Hebei Province, our facility is conveniently situated just 200 km from Xingang, Tianjin, China.

We operate on a 25,000 square meter site with total assets of 35.68 million yuan. Our team includes 186 staff members, featuring 20 senior engineers and 40 technicians. We maintain a comprehensive quality control system and are equipped with sophisticated production and testing equipment.

Our product range includes:

- Conveyor Parts: Conveyor Roller, Conveyor Idler, Conveyor Pulley, Conveyor Belt, Impact Bed, Plough Tripper, Belt Cleaner

- Conveyor Roller Parts: Bearing housing, Seals, Rubber rings

Our products are widely used in industries such as coal mining, steel production, cement, power generation, harbor operations, chemical processing, and more. We export to countries including Japan, Saudi Arabia, the United States, Venezuela, Russia, Australia, Brazil, Singapore, Chile, and Peru.

Why Choose Us

- Established Expertise: With over four decades in the industry, we bring extensive experience and expertise to every project.

- Advanced Technology: We use state-of-the-art technology and equipment to ensure the highest quality products.

- Comprehensive Quality Control: Our rigorous quality control system guarantees the reliability and performance of our products.

- Global Reach: Our products are trusted by customers worldwide, reflecting our commitment to excellence.

- Customer-Centric Approach: We prioritize customer satisfaction and offer personalized solutions to meet specific needs.

OEM Services

Cangzhou Idler Conveyor Machinery Co., Ltd. supports custom processing services to meet unique requirements. Whether you need specific designs, sizes, or materials, our team is ready to collaborate with you to create tailored solutions that fit your needs.

FAQs

-

What are the typical applications for your idlers?

- Our idlers are used in various industries, including mining, steel, cement, power, and ports. They are designed for heavy-duty applications and can handle a wide range of materials.

-

What materials are used in your idlers?

- Our idlers are made from high-quality steel, stainless steel, and aluminum, with anti-corrosive coatings for enhanced durability.

-

Can you provide custom sizes and designs for idlers?

- Yes, we offer OEM/ODM services and can customize idlers according to your specific requirements.

-

What is the typical lead time for an order?

- Lead times vary based on order size and customization. Generally, standard orders are processed within 4-6 weeks.

-

Do you offer a warranty on your products?

- Yes, we provide a warranty on our idlers, covering defects in materials and workmanship. Specific terms and conditions apply.

Packaging and Logistics

Packaging:

- Wooden Crates: For secure and robust packaging of larger orders.

- Cartons: Suitable for smaller items and standard shipments.

- Foam Padding: Used to prevent damage during transit.

- Waterproof Packaging: To protect against moisture and environmental conditions.

- Custom Packaging: Available to meet specific customer needs and branding requirements.

- International Standards: Our packaging complies with international shipping regulations.

Logistics:

- Sea Freight: Cost-effective for large shipments and long-distance transportation.

- Air Freight: Fast and reliable for urgent deliveries.

- Land Transportation: Ideal for regional deliveries within China.

- Multimodal Shipping: Combines different transport modes for efficiency and cost savings.

- Express Services: For time-sensitive shipments and urgent requests.

Contact Us

We invite global buyers and industry professionals to collaborate with Cangzhou Idler Conveyor Machinery Co., Ltd. For inquiries, custom orders, or more information about our products, please contact us at:

Email: angie@idlerchina.com

We look forward to the opportunity to work with you and provide high-quality idlers for your conveyor systems.

YOU MAY LIKE