- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

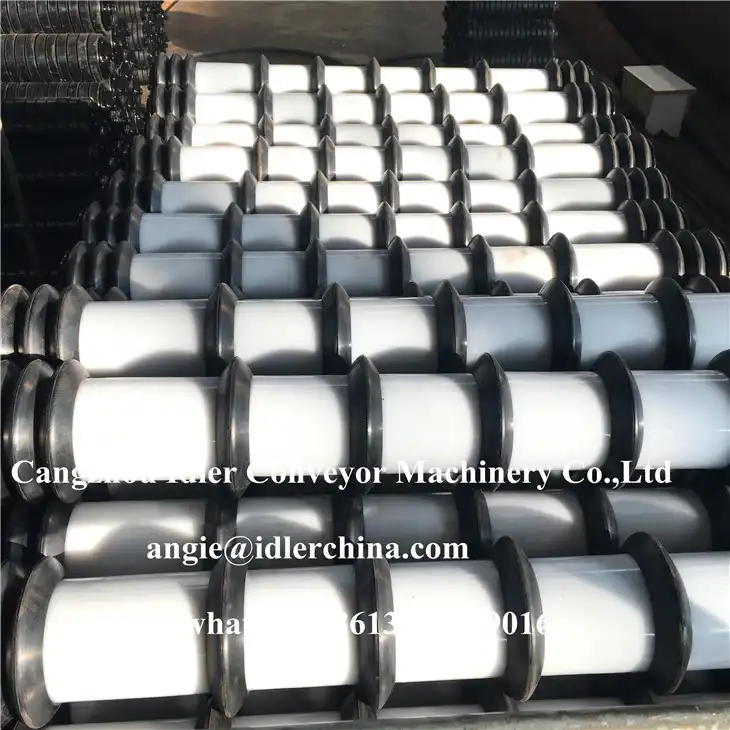

superior belt conveyor idlers

Free sample

MOQ: 1PCS

Customizable sizes to suit a variety of applications

Superior Belt Conveyor Idlers

Product Introduction

Superior belt conveyor idlers are integral components in the material handling industry, ensuring the efficient and reliable transportation of materials across various sectors. These idlers are designed to support the conveyor belt and the load being conveyed, providing a low-friction, smooth rolling surface. As a leading supplier in this field, Cangzhou Idler Conveyor Machinery Co., Ltd. brings decades of experience and expertise, ensuring top-quality products that meet global standards.

Product Specifications

Below are the detailed specifications for our superior belt conveyor idlers:

| Parameter | Value |

|---|---|

| Diameter | 89-219 mm |

| Belt Width | 400-2400 mm |

| Shaft Diameter | 20-40 mm |

| Bearing Type | Deep Groove Ball Bearing |

| Load Capacity | Up to 2500 kg |

Physical and Chemical Properties

- Material: High-strength steel

- Surface Treatment: Galvanized, powder-coated

- Corrosion Resistance: Excellent

- Temperature Range: -20°C to 80°C

Mechanical Performance

- High Load Capacity: Designed to handle significant weight without deformation.

- Low Friction: Ensures smooth belt movement, reducing wear and energy consumption.

- Durability: Made from robust materials that withstand harsh environments.

- Alignment Stability: Maintains the belt's alignment, preventing spillage and reducing maintenance needs.

- Noise Reduction: Engineered to operate quietly, improving the working environment.

Applications

Our superior belt conveyor idlers are versatile and can be used in various industries:

- Coal Mines: Ensure efficient material transport with minimal downtime.

- Steel Industry: Support heavy loads and withstand high temperatures.

- Cement Plants: Provide reliable performance in dusty conditions.

- Power Plants: Facilitate continuous material flow with high durability.

- Harbors: Ideal for bulk material handling in port operations.

- Chemical Plants: Resist corrosion from chemicals and abrasive materials.

- Grain Industry: Maintain hygiene and reduce contamination risks.

Production Process

- Raw Material Selection: High-quality steel is sourced for optimal performance.

- Cutting and Shaping: Precision cutting machines ensure accurate dimensions.

- Welding: Automated welding processes guarantee strong and consistent joints.

- Surface Treatment: Galvanizing or powder coating to enhance corrosion resistance.

- Assembly: Skilled technicians assemble the components with meticulous attention.

- Quality Control: Rigorous testing to ensure each idler meets our high standards.

Factory Introduction

Cangzhou Idler Conveyor Machinery Co., Ltd. was founded in 1980, combining scientific research, production, processing, and sales. Located in the Industrial Zone of Yanshan County, Hebei Province, just 200 km from Xingang, Tianjin, China, our company covers an area of 25,000 square meters with total assets of 35.68 million yuan. We have 186 staff members, including 20 senior engineers and 40 technicians, and a complete, effective quality control system.

Equipped with sophisticated production and testing equipment, our products enjoy a good reputation both at home and abroad. We produce various conveyor parts, including rollers, idlers, pulleys, belts, and more, widely used in coal mines, steel, cement, power, harbors, and other industries.

Packaging

Our packaging options ensure the safe and secure delivery of our products:

- Wooden Crates: Strong and durable, ideal for international shipping.

- Carton Boxes: Lightweight and cost-effective for smaller shipments.

- Foam Padding: Provides extra protection against impact and vibration.

- Waterproof Packaging: Ensures protection from moisture and humidity.

- Custom Packaging: Tailored solutions to meet specific customer needs.

- Compliance with International Standards: All packaging meets global shipping regulations.

Logistics

We offer multiple logistics options to cater to our clients' needs:

- Sea Freight: Cost-effective for large and heavy shipments.

- Air Freight: Fast delivery for urgent orders.

- Land Transportation: Reliable and efficient for regional deliveries.

- Multimodal Transport: Combining different modes for optimized delivery.

- Express Services: Swift and secure for smaller packages.

Why Choose Us

- Experience: Over 40 years in the industry, providing reliable and innovative solutions.

- Quality Control: Comprehensive testing and quality assurance processes.

- Advanced Equipment: State-of-the-art production and testing facilities.

- Skilled Workforce: Experienced engineers and technicians dedicated to excellence.

- Global Reach: Established presence in major international markets.

- Customer-Centric: Commitment to customer satisfaction and after-sales service.

- Customization: Tailored solutions to meet specific client requirements.

- Financial Stability: Strong financial position to support large-scale projects.

OEM/ODM Services

Cangzhou Idler Conveyor Machinery Co., Ltd. offers comprehensive OEM and ODM services, supporting custom design and manufacturing to meet your specific needs. Whether you need custom dimensions, materials, or features, our experienced team is ready to collaborate with you to create the perfect solution.

FAQ

- What materials are used for the idlers?

- High-strength steel with various surface treatments.

- Can the idlers be customized?

- Yes, we offer OEM/ODM services for custom specifications.

- What is the lead time for orders?

- Typically 4-6 weeks, depending on order size and customization requirements.

- How do you ensure product quality?

- Through rigorous testing and quality control processes at every production stage.

- What industries do you serve?

- Our products are used in coal mines, steel, cement, power, harbors, and more.

Contact Us

We welcome global procurement managers to collaborate with Cangzhou Idler Conveyor Machinery Co., Ltd. Our mission is to offer high-quality products and perfect after-sale service at a reasonable price. For more information, please contact us at angie@idlerchina.com. Let's work together for mutual benefit and common development.

YOU MAY LIKE