- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

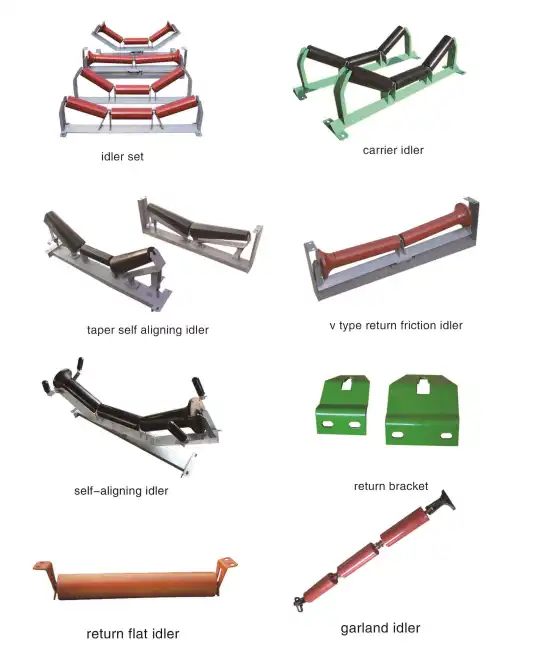

types of idler in belt conveyor

Free sample

MOQ: 1PCS

Customizable sizes to suit a variety of applications

Types of Idler in Belt Conveyor

Product Introduction

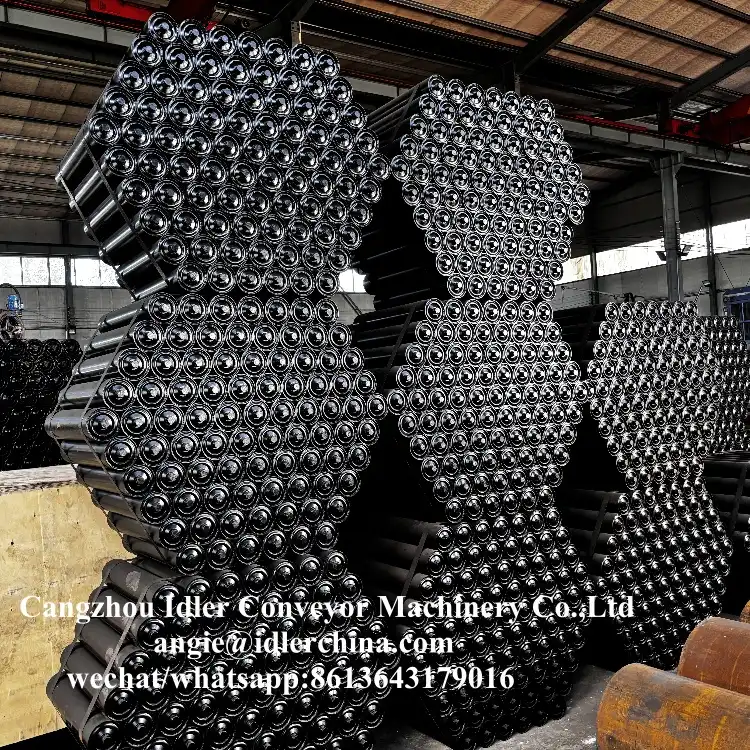

At Cangzhou Idler Conveyor Machinery Co., Ltd, we are dedicated to delivering superior conveyor solutions that meet the diverse needs of our global clientele. Since our establishment in 1980, we have specialized in the production of high-quality conveyor components, including various types of idlers used in belt conveyors. Our idlers are integral to the efficiency and longevity of conveyor systems, ensuring smooth and reliable operation in a wide range of industries.

Idlers are crucial components of belt conveyors, providing support to the conveyor belt, reducing friction, and ensuring smooth movement of materials. Our idlers are engineered to handle diverse operational conditions and material types, making them ideal for applications in industries such as mining, steel, cement, power, and more. Our commitment to quality and innovation ensures that each idler meets stringent performance and durability standards.

Our company, Cangzhou Idler Conveyor Machinery Co., Ltd, combines cutting-edge technology with extensive industry experience. Located in the Industrial Zone of Yanshan County, Hebei Province, we benefit from excellent transportation links, just 200 km from Xingang, Tianjin. With a factory spanning 25,000 square meters and a skilled workforce of 186 employees, including 20 senior engineers and 40 technicians, we are well-equipped to meet the demands of our global customers.

Product Parameters

| Parameter | Specification |

|---|---|

| Idler Type | Trough Idler, Impact Idler, Return Idler, Training Idler |

| Diameter (mm) | 50, 76, 89, 102, 114,127,152,178 |

| Length (mm) | 500, 600, 800, 1000, 1200,1400,1600,1800,2000,2200 |

| Material | Carbon Steel, Stainless Steel, Rubber |

| Bearing Type | Sealed Roller Bearing, Open Roller Bearing |

| Load Capacity (kg) | Up to 1000 kg per idler |

Physical and Chemical Properties

Our idlers are manufactured using high-quality materials that offer exceptional durability and resistance to wear and corrosion. The physical and chemical properties of our idlers include:

- Material: High-grade steel or stainless steel for maximum strength and resistance.

- Corrosion Resistance: Coated with anti-corrosion treatments to withstand harsh environmental conditions.

- Temperature Tolerance: Operate effectively in temperatures ranging from -40°C to +80°C.

- Surface Finish: Smooth and polished to reduce friction and extend the life of the conveyor belt.

Mechanical Performance

Our idlers are designed for optimal mechanical performance. Key features include:

- Load Distribution: Evenly distributes the load across the belt, reducing stress and extending conveyor life.

- Low Friction: Advanced bearing technology minimizes friction, leading to energy savings and reduced wear.

- Durability: Engineered to withstand heavy loads and harsh operating conditions, ensuring long-lasting performance.

- Noise Reduction: Designed to operate quietly, reducing noise pollution in the workplace.

Product Applications

Our idlers are versatile components used in various conveyor systems across multiple industries. Their applications include:

- Mining: Handling bulk materials such as coal, ore, and minerals with high efficiency.

- Steel: Transporting heavy steel products and ensuring smooth movement through processing lines.

- Cement: Conveying raw materials and finished products in cement plants.

- Power: Managing coal and other fuels in power generation facilities.

- Ports: Facilitating the transfer of goods in harbor and logistics operations.

Future Trends: With advancements in technology, idler designs are evolving to enhance energy efficiency and durability. Our research and development team is constantly innovating to incorporate these trends into our products.

Product Process and Production Flow

Our production process for idlers includes several key stages:

- Material Selection: High-quality raw materials are selected based on specific requirements.

- Manufacturing: Precision machining and fabrication are carried out using advanced equipment.

- Assembly: Components are assembled with attention to detail to ensure proper alignment and function.

- Quality Control: Rigorous testing is conducted to ensure each idler meets our high standards.

- Finishing: Final treatments and coatings are applied to enhance durability and appearance.

- Packaging: Idlers are carefully packed to prevent damage during transit.

About Us

Cangzhou Idler Conveyor Machinery Co., Ltd, founded in 1980, is a leading manufacturer specializing in conveyor components. Our facilities are equipped with state-of-the-art production and testing equipment, ensuring high-quality products. With an experienced team and a commitment to excellence, we serve a wide range of industries both domestically and internationally.

Our Products Include:

- Conveyor Parts: Conveyor Roller, Conveyor Idler, Conveyor Pulley, Conveyor Belt, Impact Bed, Plough Tripper, Belt Cleaner

- Conveyor Roller Parts: Bearing Housing, Seals, Rubber Rings

Our products are widely used in coal mines, steel, cement, power, harbor, chemical, screen, crusher, and grain industries. We export to countries such as Japan, Saudi Arabia, the United States, and more.

Logistics and Packaging

Packaging Options:

- Wooden Crates: Provides robust protection for large or fragile components.

- Cartons: Suitable for smaller items, offering protection and ease of handling.

- Foam Filling: Used to cushion products and prevent damage during transport.

- Waterproof Packaging: Ensures protection against moisture and environmental factors.

- Custom Packaging: Tailored to meet specific requirements or branding needs.

Logistics Options:

- Sea Freight: Cost-effective for bulk shipments over long distances.

- Air Freight: Fast delivery for urgent orders.

- Land Transport: Suitable for regional deliveries.

- Multi-modal Transport: Combines different transport methods for efficient delivery.

- Courier Services: Ideal for smaller orders or urgent shipments.

Why Choose Us?

- Established Reputation: Founded in 1980 with decades of experience.

- Advanced Technology: Equipped with modern production and testing equipment.

- Quality Assurance: Comprehensive quality control system ensuring product reliability.

- Global Reach: Serving customers worldwide with efficient logistics.

- Customer Focus: Committed to providing excellent service and support.

OEM Services

We offer customized manufacturing solutions to meet specific requirements. Our OEM/ODM services include tailored design, production, and packaging to align with your unique needs.

Frequently Asked Questions (FAQ)

-

What types of idlers do you offer? We offer various types of idlers, including trough idlers, impact idlers, return idlers, and training idlers.

-

What materials are used in your idlers? Our idlers are made from high-quality carbon steel, stainless steel, and rubber.

-

Can I get a custom design for my idlers? Yes, we provide OEM/ODM services to create custom idlers based on your specifications.

-

What is the maximum load capacity of your idlers? Our idlers can handle loads up to 1000 kg each.

-

What is the typical lead time for orders? Lead time varies based on order size and customization, but we generally deliver within 4-6 weeks.

Contact Us

For more information or to discuss your specific requirements, please contact us at angie@idlerchina.com. We look forward to partnering with you and providing solutions that meet your conveyor system needs.

YOU MAY LIKE