- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

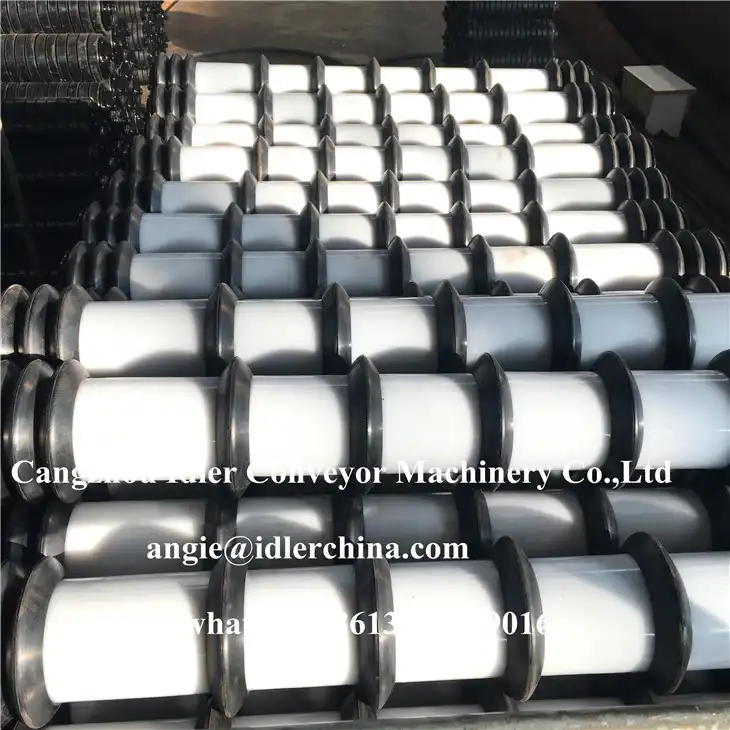

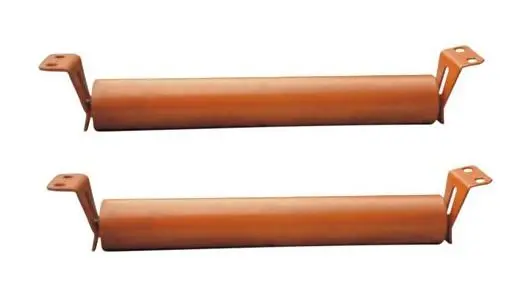

standard conveyor idler

Free sample

MOQ: 1PCS

Customizable sizes to suit a variety of applications

Standard Conveyor Idler Product Introduction

Product Introduction

At Cangzhou Idler Conveyor Machinery Co., Ltd, we pride ourselves on being a leading supplier of standard conveyor idlers. Our conveyor idlers are integral components of conveyor systems, ensuring smooth and efficient material handling in various industries, including mining, steel, cement, power, harbor, and chemical sectors.

Shaanxi Peakrise Metal Co.,Ltd, a trusted supplier of molybdenum electrodes, collaborates closely with us to ensure our products meet the highest standards of quality and performance. Our conveyor idlers are designed with precision engineering and manufactured using state-of-the-art technology, ensuring durability, reliability, and excellent performance under the harshest working conditions.

Our idlers are widely recognized for their robust construction, low maintenance requirements, and long service life, making them the preferred choice for numerous global industries. With over four decades of experience, Cangzhou Idler Conveyor Machinery Co., Ltd has established itself as a reliable partner, committed to providing high-quality products and exceptional customer service.

Product Parameter Table

General Specifications

| Parameter | Specification |

|---|---|

| Material | Carbon Steel |

| Diameter | 89mm-219mm |

| Length | 200mm - 2400mm |

| Bearing Type | Deep Groove Ball Bearing |

| Load Capacity | Up to 350kg |

| Shaft Diameter | 20mm, 25mm, 30mm |

| Shaft Material | High Tensile Steel |

| Finish | Powder Coated |

Mechanical Properties

| Property | Value |

|---|---|

| Tensile Strength | 450 MPa |

| Yield Strength | 250 MPa |

| Hardness | 60 HRC |

| Impact Resistance | High |

| Wear Resistance | Excellent |

| Corrosion Resistance | High |

Environmental Tolerance

| Condition | Range |

|---|---|

| Operating Temperature | -20°C to 80°C |

| Humidity Resistance | Up to 95% RH |

| Dust Resistance | High |

| Water Resistance | High |

Physical and Mechanical Properties

Our standard conveyor idlers boast the following properties:

- Tensile Strength: With a tensile strength of 450 MPa, our idlers are capable of withstanding significant tensile forces without deformation.

- Yield Strength: The yield strength of 250 MPa ensures that the idlers maintain their structural integrity under heavy loads.

- Hardness: A hardness rating of 60 HRC provides excellent wear resistance, ensuring a long service life.

- Impact Resistance: High impact resistance allows our idlers to absorb shock and vibrations, reducing the risk of damage.

- Corrosion Resistance: Our idlers are designed to resist corrosion, making them suitable for use in harsh environmental conditions.

Product Applications

Our standard conveyor idlers are versatile and can be applied in various industries:

- Mining: Used in conveyor systems for transporting raw materials.

- Steel Industry: Essential for handling heavy steel products and by-products.

- Cement Plants: Integral in the movement of cement and related materials.

- Power Plants: Facilitates the transportation of coal and other fuels.

- Harbors: Supports the movement of bulk cargo efficiently.

- Chemical Industry: Ensures safe and efficient transport of chemical products.

Development Trends

The continuous development in material science and engineering practices is pushing the boundaries of conveyor idler performance. Future trends indicate a move towards more sustainable and energy-efficient designs, with advancements in automation and real-time monitoring to enhance operational efficiency.

Production Process and Factory Introduction

Production Process

- Material Selection: High-quality carbon steel and high tensile steel are selected for manufacturing.

- Cutting: Precision cutting machines shape the steel into desired dimensions.

- Welding: Automated welding ensures consistent and strong joints.

- Machining: Advanced CNC machines process the idlers to precise specifications.

- Assembly: Bearings and other components are assembled with the idler bodies.

- Coating: Powder coating is applied for corrosion resistance.

- Quality Inspection: Rigorous testing ensures each idler meets industry standards.

- Packaging: Finished products are carefully packed for shipment.

Factory Introduction

Founded in 1980, Cangzhou Idler Conveyor Machinery Co., Ltd is located in the Industrial Zone of Yanshan County, Hebei Province. With an area of 25,000 square meters and total assets of 35.68 million yuan, our facility houses 186 staff members, including 20 senior engineers and 40 technicians. We have established a comprehensive quality control system, equipped with sophisticated production and testing equipment, ensuring our products meet the highest standards.

Packaging and Logistics

Packaging Options

- Wooden Crates: Robust protection for heavy-duty shipments.

- Carton Boxes: Suitable for smaller, lighter idlers.

- Foam Fill Packaging: Provides additional cushioning.

- Waterproof and Moisture-proof Packaging: Ensures safe transport in humid conditions.

- Custom Packaging: Tailored solutions to meet specific customer requirements.

- International Standard Packaging: Complies with global shipping standards.

Logistics Options

- Sea Freight: Cost-effective for large volumes.

- Air Freight: Fast delivery for urgent needs.

- Land Transport: Efficient for regional deliveries.

- Multimodal Transport: Combines various modes for optimal efficiency.

- Courier Services: Quick and reliable for smaller orders.

Why Choose Us

- Experience: Over four decades of industry expertise.

- Quality: Rigorous quality control and advanced testing equipment.

- Innovation: Continuous R&D to improve product performance.

- Global Reach: Export to over 20 countries worldwide.

- Customer Support: Excellent after-sales service.

- Customization: OEM/ODM services to meet specific requirements.

OEM Services

Cangzhou Idler Conveyor Machinery Co., Ltd offers comprehensive OEM and ODM services. We support custom designs and specifications to meet unique customer needs, ensuring high-quality, tailored solutions for any application.

Frequently Asked Questions

- What materials are used in your conveyor idlers?

- We use high-quality carbon steel and high tensile steel.

- Can you customize idlers to specific dimensions?

- Yes, we offer OEM services to customize idlers according to your requirements.

- What is the lead time for an order?

- Lead time varies based on order quantity and specifications, typically ranging from 2 to 4 weeks.

- How do you ensure product quality?

- We have a comprehensive quality control system and conduct rigorous testing on all products.

- What industries use your conveyor idlers?

- Our idlers are widely used in mining, steel, cement, power, harbor, and chemical industries.

Contact Us

Ready to improve your material handling systems with high-quality conveyor idlers? Contact Cangzhou Idler Conveyor Machinery Co., Ltd today. We look forward to establishing a long-term partnership with you. Reach us at angie@idlerchina.com.

Conclusion

Cangzhou Idler Conveyor Machinery Co., Ltd is committed to providing superior quality conveyor idlers that meet the needs of various industries worldwide. With our advanced production processes, rigorous quality control, and excellent customer service, we aim to be your trusted partner in achieving efficient and reliable material handling solutions. Contact us today to learn more about our products and services.

YOU MAY LIKE