- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

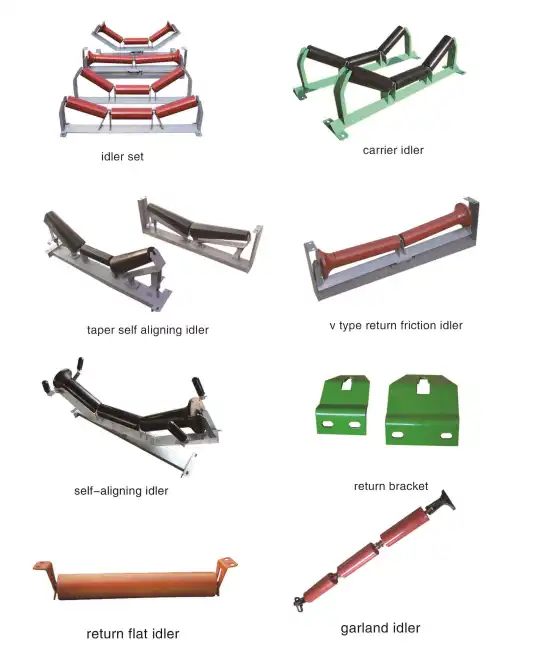

impact idlers used in a belt conveyor

Impact Conveyor Idlers: Product Introduction

Welcome to Cangzhou Idler Conveyor Machinery Co., Ltd., a leading manufacturer specializing in high-quality conveyor components. Established in 1980, our company is committed to providing innovative solutions for the conveyor industry. This page highlights our impact conveyor idlers, essential components designed to withstand heavy loads and impact forces in belt conveyor systems.

Product Introduction

Impact conveyor idlers play a crucial role in belt conveyor systems, particularly in applications where material flow involves heavy and abrasive substances. These idlers are strategically placed at the loading zones to absorb the shock and distribute the load evenly, ensuring the longevity and efficiency of the conveyor system. At Cangzhou Idler Conveyor Machinery Co., Ltd., our impact idlers are engineered to meet the highest standards of durability and performance, making them ideal for various industrial applications.

Our impact idlers are designed with a robust structure, featuring high-strength materials and advanced engineering techniques to handle extreme conditions. They are widely used in industries such as mining, cement, steel, and power generation, where they help minimize wear and tear on conveyor belts and reduce maintenance costs.

Product Parameters

| Parameter | Specification |

|---|---|

| Roller Diameter | 89 mm, 102 mm, 114 mm |

| Roller Length | 500 mm, 600 mm, 1000 mm |

| Tube Material | Carbon Steel, Stainless Steel |

| Shell Thickness | 3 mm, 4 mm, 5 mm |

| Bearing Type | Sealed, Self-lubricating |

| Load Capacity | 500 kg to 2000 kg |

| Impact Resistance | Up to 1000 Joules |

| Temperature Range | -20°C to +60°C |

Physical and Mechanical Properties

- Material Composition: Our impact idlers are made from high-quality carbon steel or stainless steel, providing excellent resistance to corrosion and wear.

- Impact Resistance: Engineered to absorb shock and reduce impact forces, our idlers feature enhanced impact resistance to protect the conveyor belt.

- Load Bearing Capacity: Designed to handle heavy loads with ease, our idlers are tested for high load-bearing capacity, ensuring reliable performance in demanding environments.

- Temperature Tolerance: Our impact idlers operate efficiently across a wide temperature range, making them suitable for various industrial settings.

Product Applications

- Mining Industry: Impact idlers are essential in mining operations where they absorb the impact of heavy ore and rock, reducing the wear on conveyor belts and extending their service life.

- Cement Production: In cement plants, impact idlers help manage the heavy and abrasive nature of cement and clinker, ensuring smooth and efficient material handling.

- Steel Manufacturing: Used in steel mills, our idlers support the transportation of heavy steel products and scrap metal, minimizing operational disruptions.

- Power Generation: Impact idlers are employed in power plants to handle the transportation of coal and other bulk materials, contributing to the overall efficiency of the power generation process.

Production Processes and Workflow

- Material Selection: High-quality raw materials are selected based on their durability and performance characteristics.

- Manufacturing: State-of-the-art machinery is used to manufacture impact idlers, ensuring precise dimensions and quality.

- Assembly: Components are assembled with meticulous attention to detail, incorporating advanced technology to enhance performance.

- Testing: Rigorous testing procedures are conducted to ensure each idler meets the required standards for impact resistance, load capacity, and overall durability.

- Quality Control: A comprehensive quality control system is in place to monitor every stage of production, ensuring consistent product quality.

Company Introduction

Cangzhou Idler Conveyor Machinery Co., Ltd. is a well-established enterprise with a rich history in the conveyor industry. Founded in 1980, our company integrates scientific research, production, processing, and sales. We are located in the Industrial Zone, Yanshan County, Hebei Province, China, with excellent transportation links, being just 200 km from Xingang, Tianjin.

Our facility covers an area of 25,000 square meters and boasts total assets of 35.68 million yuan. With 186 staff members, including 20 senior engineers and 40 technicians, we have developed a robust quality control system. Our advanced production and testing equipment ensure that our products meet international standards and are highly regarded both domestically and internationally.

Logistics and Packaging

- Wooden Crate Packaging: Provides robust protection for impact idlers during transportation, minimizing the risk of damage.

- Carton Packaging: Suitable for smaller quantities, ensuring the safe delivery of products to various destinations.

- Foam Padding: Used to cushion products and prevent movement within packaging, offering additional protection against impacts.

- Waterproof and Moisture-proof Packaging: Essential for protecting products from environmental factors during transit.

- Custom Packaging: Tailored solutions to meet specific requirements, enhancing product safety and presentation.

- International Standard Packaging: Ensures compliance with global shipping regulations and standards.

Logistics

- Sea Freight: Cost-effective solution for bulk shipments, offering reliable and timely delivery to international ports.

- Air Freight: Ideal for urgent shipments, providing faster delivery times to global destinations.

- Land Transportation: Efficient for regional deliveries, ensuring timely distribution within the domestic market.

- Multimodal Transportation: Combines different modes of transport to optimize delivery times and costs.

- Express Services: For urgent and smaller shipments, ensuring rapid delivery to clients worldwide.

Why Choose Us?

- Experience: With over four decades of experience, we have established ourselves as a leader in the conveyor industry.

- Quality: Our products are manufactured using high-quality materials and advanced technology, ensuring superior performance.

- Innovation: We continually invest in research and development to offer innovative solutions that meet the evolving needs of our clients.

- Customer Service: Our dedicated team provides exceptional support and service, addressing any inquiries and ensuring customer satisfaction.

- Global Reach: Our products are exported to numerous countries, reflecting our commitment to quality and international standards.

OEM Services

Cangzhou Idler Conveyor Machinery Co., Ltd. offers comprehensive OEM services, providing customized solutions to meet specific client requirements. Whether you need tailored designs or unique specifications, our team is equipped to deliver high-quality, bespoke products that align with your needs.

FAQs

-

What are impact conveyor idlers used for? Impact idlers are designed to absorb shock and impact forces in belt conveyor systems, protecting the conveyor belt from damage and ensuring smooth operation.

-

What materials are used in the construction of impact idlers? Our impact idlers are made from high-quality carbon steel or stainless steel, providing excellent durability and resistance to wear and corrosion.

-

Can impact idlers be customized? Yes, we offer OEM services to customize impact idlers according to your specific requirements, including size, material, and design.

-

What is the load capacity of your impact idlers? Our impact idlers have a load capacity ranging from 500 kg to 2000 kg, depending on the model and application.

-

How do you ensure the quality of your products? We employ a comprehensive quality control system, including rigorous testing and inspection procedures, to ensure that our products meet the highest standards.

Contact Us

We invite global buyers and partners to collaborate with Cangzhou Idler Conveyor Machinery Co., Ltd. For inquiries or to discuss your needs, please contact us at angie@idlerchina.com. We look forward to the opportunity to work with you and provide solutions that meet your conveyor system requirements.

YOU MAY LIKE