- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

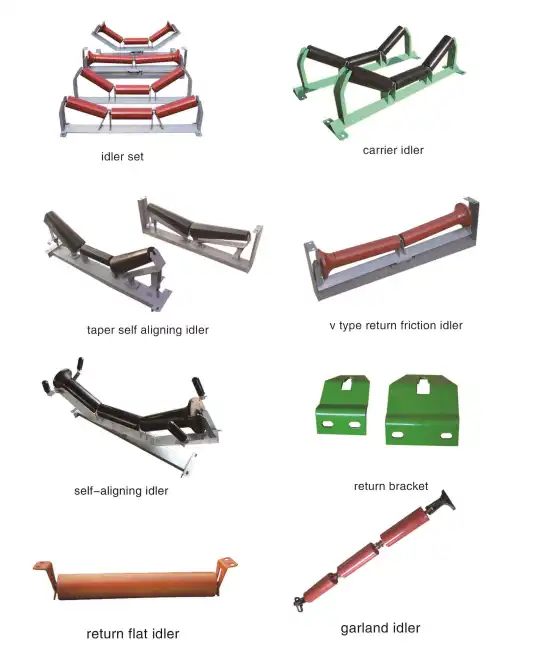

belt conveyor impact idler roller

Belt Conveyor Impact Idler Roller - Product Introduction

Product Introduction

The Belt Conveyor Impact Idler Roller is an essential component in conveyor systems, designed to support and absorb impacts from heavy materials and reduce wear and tear on the conveyor belt. At Cangzhou Idler Conveyor Machinery Co., Ltd., we specialize in producing high-quality impact idler rollers that ensure optimal performance and durability in various industrial applications.

Our impact idler rollers are engineered to withstand high-impact loads and severe operating conditions, making them ideal for use in mining, construction, and bulk material handling. With a focus on precision manufacturing and quality control, our products offer superior reliability and longevity.

Founded in 1980, Cangzhou Idler Conveyor Machinery Co., Ltd. is a leading manufacturer in the conveyor machinery industry. Our factory, located in the Industrial Zone of Yanshan County, Hebei Province, China, is equipped with advanced production and testing facilities. We are committed to providing innovative and efficient solutions to our global clients, with our products renowned for their quality and performance.

Product Parameters

| Parameter | Specification |

|---|---|

| Roller Diameter | 89mm, 108mm, 114mm |

| Roller Length | 1000mm, 1200mm, 1500mm |

| Wall Thickness | 4mm, 5mm, 6mm |

| Shaft Diameter | 20mm, 25mm, 30mm |

| Bearing Type | 6204, 6205, 6206 |

| Material | Steel, Rubber |

| Max Load Capacity | 5000kg |

| Temperature Range | -20°C to +80°C |

Physical and Chemical Properties

- Material Composition: Our impact idler rollers are primarily made from high-quality steel, which ensures strength and durability. The rollers are coated with a layer of rubber to enhance their impact resistance and reduce noise.

- Corrosion Resistance: The steel components are treated with anti-corrosion coatings to ensure longevity even in harsh environmental conditions.

- Impact Resistance: The rubber covering provides excellent shock absorption, reducing the impact on the conveyor belt and extending its lifespan.

Mechanical Performance

- Load Bearing Capacity: Designed to handle high-impact loads, our idler rollers maintain structural integrity under heavy operational stress.

- Durability: The combination of steel and rubber construction ensures that our rollers are resistant to wear and tear, reducing the need for frequent replacements.

- Smooth Operation: Precision-engineered bearings and shafts provide smooth and efficient roller rotation, minimizing friction and energy consumption.

Product Applications

- Mining Industry: Used for transporting bulk materials such as ores and minerals, our impact idler rollers enhance the efficiency and reliability of conveyor systems in mining operations.

- Construction: Ideal for handling construction materials like sand, gravel, and aggregates, these rollers contribute to the smooth operation of conveyor systems on construction sites.

- Power Plants: Utilized in power plants for coal handling, our rollers help in managing the high-impact loads associated with coal transport.

Manufacturing Process and Production Flow

1.Use automatic pipe cutting machine to cut steel pipe which for making conveyor roller specially into fixed length. This type of steel pipe is more precise than seamless steel pipe and ordinary straight seam steel pipe and can reduce conveyor roller’s run out.

2.Turning steel pipe inside diameter to install bearing housing

3.Welding bearing housing

4.Mill conveyor roller shaft with flat or groove end

5.Mill circlip groove on conveyor roller shaft

6.Press assemble conveyor roller labyrinth seals and bearing.We will choose TK labyrinth seals which have great advantage in dust proof and water proof and high quality raw material of ABS,Nylon,Hdpe,Polyurethane and so on.

7.Surface Treatment: Anti-corrosion treatments are applied to enhance durability.

8.Quality Control: Rigorous testing is conducted to ensure each product meets our high standards.

9.Packaging: Products are carefully packaged to prevent damage during transportation.

Company Introduction

Cangzhou Idler Conveyor Machinery Co., Ltd. has been a prominent player in the conveyor machinery industry since its inception in 1980. Our factory spans 25,000 square meters and employs 186 staff members, including 20 senior engineers and 40 technicians. Our state-of-the-art facilities and stringent quality control systems enable us to produce top-notch conveyor components. We cater to diverse industries such as coal mining, steel, cement, and more, with products exported to over 10 countries.

Logistics and Packaging

-

Packaging:

- Wooden Crates: For secure and sturdy protection during transit.

- Cartons: For lighter and less fragile components.

- Foam Fill: To cushion products and prevent damage.

- Waterproof Packaging: To safeguard against moisture and environmental damage.

- Custom Packaging: Tailored solutions based on customer requirements.

- International Standards: Packaging complies with global shipping standards.

-

Logistics:

- Sea Freight: Cost-effective for large shipments.

- Air Freight: Faster delivery for urgent orders.

- Land Transport: Reliable for regional deliveries.

- Multimodal Transport: Combining various transport modes for efficiency.

- Courier Services: For small, time-sensitive orders.

Why Choose Us?

- Established Expertise: Over four decades of experience in conveyor machinery manufacturing.

- Advanced Facilities: State-of-the-art production and testing equipment.

- Quality Assurance: Rigorous quality control systems and testing procedures.

- Global Reach: Products exported to numerous countries with a solid international reputation.

- Customer Focused: Commitment to high-quality products and excellent after-sales service.

OEM Services

Cangzhou Idler Conveyor Machinery Co., Ltd. offers comprehensive OEM and ODM services, providing customized solutions to meet specific customer needs. We work closely with clients to develop tailored products that align with their operational requirements and quality standards.

FAQ

-

What materials are used in the impact idler roller?

- The roller is primarily made from high-quality steel with a rubber coating for impact resistance.

-

What is the maximum load capacity of the idler roller?

- Our impact idler rollers can handle up to 5000kg of load.

-

Can the rollers be customized for specific dimensions?

- Yes, we offer customization options to meet specific dimension requirements.

-

What is the temperature range for the impact idler rollers?

- The rollers operate effectively within a temperature range of -20°C to +80°C.

-

How long is the typical lead time for orders?

- Lead times vary based on order size and customization but generally range from 4 to 6 weeks.

Contact Us

For more information about our Belt Conveyor Impact Idler Rollers and to discuss your specific needs, please contact us at angie@idlerchina.com. We look forward to establishing a long-term partnership with you and delivering top-quality products that meet your expectations.

.

YOU MAY LIKE