- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

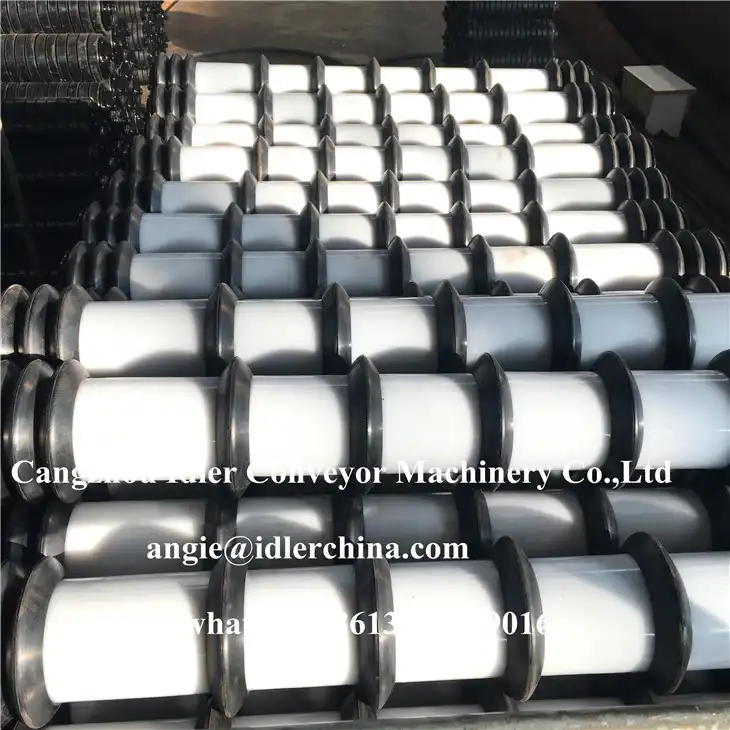

standard conveyor cema idler roller

Free sample

MOQ: 1PCS

Customizable sizes to suit a variety of applications

Standard Conveyor CEMA Idler Roller

Product Introduction

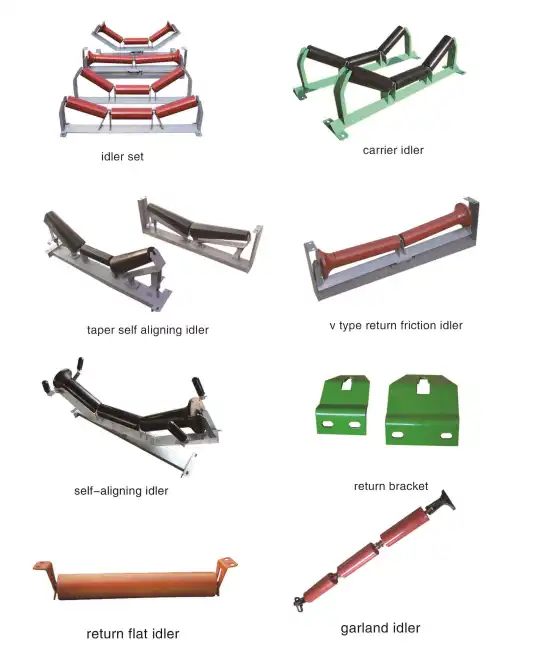

The standard conveyor CEMA idler roller, an integral component of conveyor systems, ensures the efficient and smooth transportation of materials. These rollers are crucial for reducing friction, enhancing the lifespan of conveyor belts, and minimizing maintenance requirements. At Shaanxi Peakrise Metal Co., Ltd., a leading supplier of molybdenum electrodes, we bring you high-quality CEMA idler rollers designed to meet the rigorous demands of various industries, including mining, steel, cement, power, and harbor sectors.

Our idler rollers are manufactured to the highest standards, ensuring durability, reliability, and optimal performance. Each roller undergoes stringent quality checks to ensure it meets industry specifications and client expectations. With advanced production techniques and a deep understanding of material science, we produce idler rollers that are not only efficient but also cost-effective, providing excellent value for your investment.

Product Parameters

| Parameter | Value |

|---|---|

| Roller Diameter | 89 mm, 108 mm, 127 mm,152mm,178mm |

| Shaft Diameter | 20 mm, 25 mm, 30 mm,35mm,40mm |

| Roller Length | 200 mm to 2500 mm |

| Bearing Type | Deep Groove Ball Bearing |

| Load Capacity | Up to 250 kg |

| Operating Temperature Range | -20°C to 80°C |

Physicochemical Properties

- Material: High-strength steel, corrosion-resistant coatings

- Surface Treatment: Zinc plating, powder coating

- Hardness: HRC 55-60

- Corrosion Resistance: Excellent in various environments

- Wear Resistance: High, ensuring long service life

Mechanical Properties

- Load Bearing: Each roller can handle significant loads without deforming or losing performance.

- Friction Reduction: Designed to minimize friction, thereby reducing wear on the conveyor belt and enhancing efficiency.

- Impact Resistance: Can withstand substantial impact forces, making them suitable for heavy-duty applications.

- Rotational Precision: Ensures smooth and consistent rotation, critical for maintaining conveyor speed and reliability.

Product Applications

- Mining Industry: Facilitates the transportation of heavy materials, reducing operational costs and downtime.

- Steel Manufacturing: Ensures efficient handling of raw materials and finished products, improving productivity.

- Cement Plants: Essential for the continuous movement of bulk materials, enhancing process efficiency.

- Power Plants: Supports the reliable conveyance of coal and other materials, ensuring uninterrupted power generation.

- Harbors: Ideal for the efficient loading and unloading of cargo, improving turnaround times.

- Chemical Industry: Handles a variety of chemicals with ease, maintaining integrity and performance under challenging conditions.

Production Process

- Material Selection: High-quality steel is sourced and inspected.

- Cutting and Shaping: Steel is cut and shaped to precise dimensions using advanced machinery.

- Surface Treatment: Rollers undergo surface treatments like zinc plating or powder coating for corrosion resistance.

- Assembly: Components are assembled with precision, ensuring proper alignment and performance.

- Quality Inspection: Each roller is rigorously tested for dimensional accuracy, load capacity, and performance.

- Packaging: Finished products are securely packaged for transport.

Factory Introduction

Founded in 1980, Cangzhou Idler Conveyor Machinery Co., Ltd. combines scientific research, production, processing, and sales. Located in the Industrial Zone of Yanshan County, Hebei Province, we benefit from convenient transportation, being only 200 km away from Xingang, Tianjin, China.

Our facility spans 25,000 square meters and boasts total assets of 35.68 million yuan. With 186 dedicated staff members, including 20 senior engineers and 40 technicians, we have established a comprehensive and effective quality control system. Our company is equipped with sophisticated production and testing equipment and a complete testing system. Thanks to advanced equipment and professional experience, our products enjoy a good reputation both domestically and internationally.

Logistics and Packaging

Packaging Options:

- Wooden Crates: Secure and durable for heavy-duty items.

- Cardboard Boxes: Lightweight and economical for smaller shipments.

- Foam Filling: Provides additional protection against shocks.

- Waterproof and Moisture-Proof Packaging: Ensures products remain in optimal condition during transport.

- Customized Packaging: Tailored solutions to meet specific client needs.

- International Standard Packaging: Complies with global shipping regulations.

Logistics Options:

- Sea Freight: Cost-effective for large shipments.

- Air Freight: Fast delivery for urgent needs.

- Land Transport: Reliable and flexible for regional deliveries.

- Multimodal Transport: Combines different transportation modes for efficiency.

- Express Services: Quick and convenient for small packages.

Why Choose Us

- Experience: Over 40 years of expertise in conveyor machinery production.

- Quality Assurance: Comprehensive quality control system ensuring top-notch products.

- Advanced Equipment: State-of-the-art machinery for precise manufacturing.

- Skilled Workforce: Experienced engineers and technicians.

- Customer Focus: Dedicated to providing excellent after-sales service.

- Global Reach: Products exported to numerous countries worldwide.

- Innovation: Continuous improvement and adoption of the latest technologies.

OEM/ODM Services

Cangzhou Idler Conveyor Machinery Co., Ltd. offers extensive OEM and ODM services to cater to your specific needs. Our team of experts will work closely with you to develop customized solutions that meet your unique requirements. Whether you need bespoke designs or tailored performance specifications, we have the capabilities to deliver high-quality, personalized products.

Frequently Asked Questions (FAQ)

-

What materials are used in your idler rollers?

- We use high-strength steel with corrosion-resistant coatings.

-

Can you customize the dimensions of the rollers?

- Yes, we offer customized dimensions to meet specific client needs.

-

What is the lead time for bulk orders?

- Typically, it ranges from 4 to 6 weeks depending on order size and specifications.

-

Do you provide samples for testing?

- Yes, we can provide samples for quality evaluation.

-

What are the payment terms?

- We accept various payment terms, including T/T, L/C, and more.

Contact Us

We invite global buyers to partner with Cangzhou Idler Conveyor Machinery Co., Ltd. for reliable and high-quality conveyor solutions. Contact us at angie@idlerchina.com for inquiries and to discuss how we can meet your conveyor machinery needs. Let's build a successful partnership together.

YOU MAY LIKE